PE wax stands for Polyethylene Wax. It is a synthetic wax made from polyethylene, a polymer made from ethylene monomers. Polyethylene Wax is commonly used as a processing aid, lubricant, and release agent in various industries.

Polyethylene Wax has a low molecular weight and is characterized by its hardness, toughness, and excellent low-temperature properties. It is also highly resistant to water and chemicals, making it suitable for use in a wide range of applications, including coatings, adhesives, inks, plastics, and rubber.

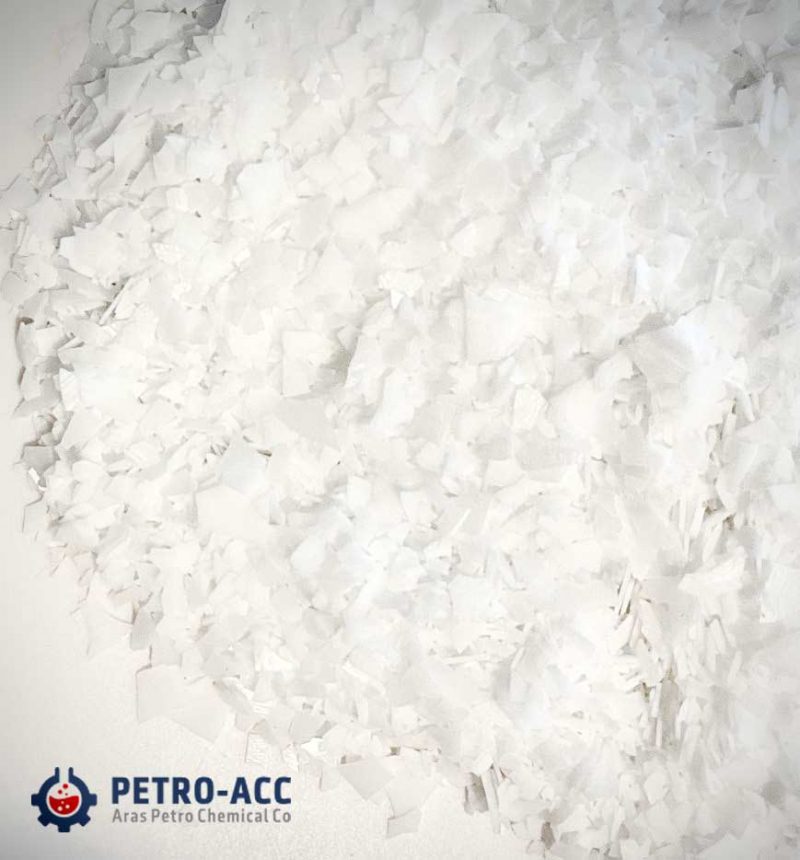

PE wax is available in various forms such as powder, flake, or granules, and its properties can be adjusted by varying its molecular weight and degree of branching. Its versatility and wide range of applications make PE wax a popular choice in many industries.

PE WAX PHYSICAL PROPERTIES

PE wax, also known as polyethylene wax. It is used in a variety of industries, including plastics, coatings, adhesives, and printing inks, due to its unique physical properties.

Some of the physical properties of PE wax include:

- Molecular Weight: Polyethylene Wax has a relatively low molecular weight compared to other types of waxes. This makes it a softer wax that has a lower melting point.

- Melting Point: Polyethylene Wax typically has a melting point ranging from 105°C to 135°C, depending on the specific grade of the wax.

- Density: Polyethylene Wax has a density ranging from 0.91 to 0.94 g/cm3, making it a relatively lightweight wax.

- Hardness: Polyethylene Wax is a relatively soft wax, with a hardness ranging from 2 to 4 on the Mohs scale.

- Slipperiness: Polyethylene Wax has a high degree of slipperiness, making it an excellent lubricant for plastics and other materials.

- Chemical Resistance: Polyethylene Wax is highly resistant to chemicals, making it an ideal choice for coatings and other applications where chemical resistance is important.

- Water Repellency: Polyethylene Wax is hydrophobic, meaning it repels water. This makes it an excellent choice for coatings and other applications where water repellency is important.

Overall, the physical properties of PE wax make it a versatile material with a wide range of applications across many different industries.

PE WAX CHEMICAL PROPERTIES

PE wax, also known as polyethylene wax, is a synthetic wax that is derived from the polymerization of ethylene. It is a type of low molecular-weight polyethylene that is commonly used as a lubricant, release agent and processing aid in various industries.

Here are some of the chemical properties of Polyethylene Wax:

- Chemical composition: Polyethylene Wax is a mixture of long-chain hydrocarbons, which are primarily made up of carbon and hydrogen atoms.

- Molecular weight: Polyethylene Wax has a low molecular weight, which typically ranges from 1000 to 10000 g/mol.

- Melting point: The melting point of Polyethylene Wax varies depending on its molecular weight and degree of branching. Generally, it has a melting point in the range of 100-130°C.

- Solubility: PE wax is insoluble in water but is soluble in many organic solvents, such as aliphatic hydrocarbons, chlorinated solvents, and aromatic hydrocarbons.

- Thermal stability: PE wax has good thermal stability, and it can withstand high temperatures without undergoing significant degradation.

- Chemical stability: PE wax is chemically stable and resistant to acids, bases, and many organic solvents.

- Lubrication properties: Polyethylene Wax exhibits excellent lubrication properties, and it is commonly used as a lubricant and release agent in various industries, including plastics, rubber, and coatings.

- Processing aid: Polyethylene Wax is also used as a processing aid in the production of various products, such as PVC, where it helps to improve the processing and handling characteristics of the material.

Overall, PE wax is a versatile material that exhibits a range of useful chemical properties, which make it suitable for a wide variety of industrial applications.

Leave A Comment