Project Description

Cementing would be one of the most important processes of oil rig drilling and by making Cementing Slurry with Gilsonite additives the costs would be lower by about 38% in comparison to using other additives.

We are an experienced supplier of Gilsonite for Cementing with high quality and competitive prices.

| Name | Gilsonite for Cementing |

| Manufacturer | PETRO-ACC |

| Made By | Aras Petrochemical Company |

| Product Code | ACC981 |

FEATURES OF USING GILSONITE FOR CEMENTING SLURRY

All over the world, in difficult areas for drilling, Gilsonite is used as an important material in cement slurry during the Drilling fluids process of oil and gas wells for more than 50 years.

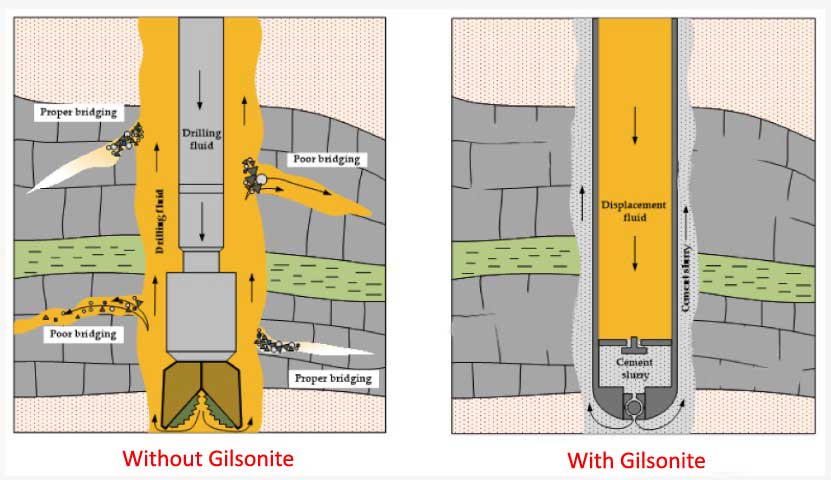

Big drilling companies when adding Gilsonite during Cementing process will help to isolate hydrocarbon formations and prevent annular gas flow and it is very important in Drilling Fluids operations.

Gilsonite will give very special benefits to Cementing Slurry follow to its special Physical and Chemical properties in comparison to other additives.

BENEFITS OF USING GILSONITE IN CEMENTING SLURRY

We mentioned here for you some of the Benefits of using Gilsonite in Cementing:

- Increases slurry performance

- It will make the slurry lighter

- Prevents the penetration of free groundwater into the well

- Reduces the amount of water in the slurry

- Prevents the loss of slurry circulation during drilling

- Prevents well from falling

- Reduces the amount of mud in the well

HOW GILSONITE INCREASING CEMENTING SLURRY BENEFITS

Gilsonite according to its special chemical and physical properties will increase the benefits of Slurry, for example, Maintains compressive strength, unlike coal or fly ash, Increases flexibility, Reduces cracking, Heals micro-fissures, Reduces permeability, Strengthens bonds to the formation and the casing, Reduces environmental risk, Assures zonal isolation and many other items will change when big drilling companies are using Gilsonite.

GILSONITE WILL CONTROL FREE WATERS

Gilsonite alone is able to control the infiltration of open groundwater and to control these waters, it is not necessary to inject and add additives to the slurry and Exactly this property of Gilsonite is one of the most important issues in the economic use of Gilsonite in cement slurry of oil and gas wells.

GILSONITE FOR CEMENTING SPECIFICATION

| SPECIFICATION | TEST METHOD | A.S.T.M |

| Ash content | 5-7% | D3174-4 |

| Solubility in CS2 | 81 | D2042 |

| Fixed Carbon | 24 | D3172 |

| Hydrogen Content | 6.5 | Elemental Analyzer |

| Sulfur Content | 0.3 | Elemental Analyzer |

| Carbon | 82 | Elemental Analyzer |

| Moisture Content | 1% | D3174 |

| Penetration | 0 | D5 |

| Specific gravity @ 25 C° | 1.04 – 1.06 | D3172 |

| Softening Point | 250-260 | E28-92 |

Leave A Comment