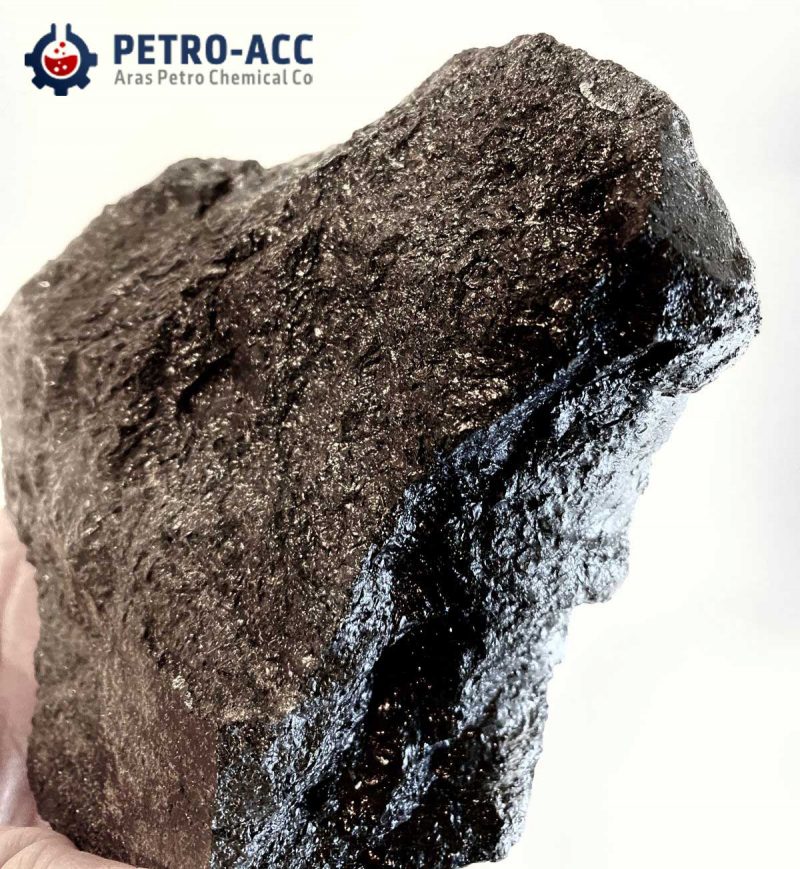

Gilsonite, also known as uintaite, is a naturally occurring mineral hydrocarbon that is mined from the earth. It is commonly used in the oil and gas industry as an additive to drilling fluids.

Here are some uses of Gilsonite in drilling fluids:

- Rheology Modifier: Gilsonite can act as a rheology modifier, which means it can help control the viscosity and flow properties of drilling fluids. It can be used to improve the suspension and stability of drilling mud, as well as to reduce fluid loss and prevent differential sticking.

- Lubricant: Gilsonite can also act as a lubricant, which helps to reduce friction and wear in the drilling process. This can be particularly useful in drilling through hard rock formations or abrasive soils.

- Lost Circulation Material: Gilsonite can also be used as a lost circulation material, which means it can help to prevent the loss of drilling fluids into porous or fractured formations. This can be important in maintaining wellbore stability and preventing blowouts.

- Sealant: Gilsonite can also act as a sealant, which means it can help to plug or seal fractures in the rock formation. This can be particularly useful in preventing the migration of fluids from one formation to another.

Overall, Gilsonite is a versatile additive to drilling fluids, and its unique properties make it an effective solution for a wide range of drilling challenges.

GILSONITE BENEFITS IN DRILLING FLUIDS

Gilsonite, also known as natural asphalt and when added to drilling fluids, Gilsonite offers several benefits, including:

- Increased lubrication: Gilsonite is an excellent lubricant that can reduce the friction between the drill bit and the formation being drilled, which can reduce wear and tear on the equipment and help prevent drill string failures.

- Improved shale stabilization: The addition of Gilsonite to the drilling process can help stabilize shale formations by reducing their tendency to swell and/or collapse, which can help prevent wellbore instability issues such as stuck pipes or lost circulation.

- Enhanced fluid loss control: Gilsonite is also effective at controlling fluid loss in drilling fluids, which can help maintain the integrity of the wellbore and improve drilling efficiency.

- Higher temperature resistance: Compared to other drilling fluid additives, Gilsonite has higher thermal stability, which means it can withstand higher temperatures without degrading, making it suitable for use in high-temperature drilling environments.

- Environmentally friendly: Gilsonite is a natural and biodegradable product, making it an environmentally friendly alternative to some of the synthetic drilling fluid additives.

METHODS OF USING GILSONITE IN DRILLING FLUIDS

Gilsonite can be added to drilling fluids to improve their rheological properties and enhance their performance. Here are some common methods of using Gilsonite in drilling fluids:

- As a viscosifier: Gilsonite can be added to drilling fluids to increase their viscosity and improve their carrying capacity. It can also help to reduce fluid loss, which can improve wellbore stability and reduce formation damage.

- As a shale inhibitor: Gilsonite can be used as a shale inhibitor to prevent the swelling and dispersion of shale formations. This can help to reduce the risk of wellbore instability and improve drilling efficiency.

- As a lubricant: Gilsonite can be used as a lubricant to reduce friction and wear on the drilling equipment. This can help to extend the life of the equipment and improve drilling efficiency.

- As a weighting agent: Gilsonite can be used as a weighting agent to increase the density of drilling fluids. This can be particularly useful in situations where a high-density fluid is required to control well pressure or to prevent fluid invasion into permeable formations.

- As a lost circulation material: Gilsonite can be used as a lost circulation material to seal off fractures and other areas of lost circulation in the formation. This can help to reduce fluid loss and improve wellbore stability.

HOW MIXING GILSONITE WITH DRILLING FLUIDS ADDITIVES

Gilsonite is a natural, resinous hydrocarbon that is commonly used as a drilling fluid additive to enhance the performance of the drilling fluid system. Here are some general steps to mix Gilsonite with drilling fluids additives:

- Determine the desired Gilsonite concentration: The amount of Gilsonite that needs to be added to the drilling fluid will depend on the specific drilling conditions, such as temperature, pressure, and formation characteristics. Typically, Gilsonite is added to drilling fluids at concentrations between 1% and 5% by weight.

- Prepare the drilling fluid: Start by mixing the drilling fluid components together in a mixing tank or vessel. Additives such as viscosifiers, shale inhibitors, and fluid loss control agents may already be included in the drilling fluid system.

- Add the Gilsonite: Slowly add the Gilsonite powder to the drilling fluid while stirring continuously to ensure that it is evenly dispersed. It is important to avoid adding too much Gilsonite at once, as this can cause clumping and difficulty in dispersing.

- Mix thoroughly: Continue to mix the drilling fluid and Gilsonite until the Gilsonite is fully dispersed and the mixture is homogeneous. This may take several minutes of vigorous stirring.

- Test the drilling fluid: Before using the drilling fluid on the well, it is important to test the rheological properties of the drilling fluid to ensure that it meets the desired specifications. If necessary, adjust the drilling fluid by adding additional additives to achieve the desired properties.

It is also important to follow the manufacturer’s instructions for the specific Gilsonite product being used and to take appropriate safety precautions when handling and mixing the drilling fluid additives.

GILSONITE REDUCES DRILLING FLUIDS COSTS

When Gilsonite is added to drilling fluids, it can help reduce costs by improving drilling efficiency, reducing waste, and enhancing the performance of the drilling fluid.

One of the main benefits of using Gilsonite in drilling fluids is its ability to enhance the lubricity and viscosity of the fluid. This can help reduce the friction between the drill bit and the formation, which in turn can help increase drilling speed and reduce the amount of energy required to drill the well. By improving the lubricity of the drilling fluid, Gilsonite can also help extend the life of the drill bit, which can result in cost savings for drilling operators.

In addition to its lubricating properties, Gilsonite can also help reduce the amount of fluid lost to the formation during drilling, which can help reduce waste and lower drilling costs. Gilsonite can act as a sealant, helping to prevent fluid loss and maintain wellbore stability.

The percentage of cost reduction by using gilsonite in drilling operations can vary depending on several factors such as the specific drilling project, the type of drilling mud used, the amount of gilsonite added, and the prevailing market prices for drilling materials.

According to some industry estimates, the addition of gilsonite to drilling mud can result in cost savings of up to 25% compared to conventional drilling muds. However, the actual percentage of cost reduction may vary based on the specific drilling project and the factors mentioned above. It’s always recommended to consult with a drilling fluids specialist to determine the optimal gilsonite dosage and potential cost savings for a specific project.

Overall, the use of Gilsonite in drilling fluids can help improve drilling performance, reduce costs, and minimize environmental impact.

Leave A Comment